Unlock Performance: Top Planetary Gears for Humanoid Robotics

Torque Efficient Planetary Gear Solutions

Unleash the full potential of your robotic applications with our torque-efficient planetary gear solutions. Designed for optimal performance, these advanced gear systems deliver superior torque output while maximizing energy efficiency, making them ideal for a variety of robotic applications.

Our innovative planetary gears minimize energy loss and ensure smooth, reliable operation, allowing your robot to perform complex tasks with ease. Focused on durability and precision, our solutions are designed to meet the demands of any environment, delivering consistent performance you can count on.

Enhance your robotics projects with our high-torque gear solutions and experience the perfect combination of power and efficiency. **Change your design today! **

Quality Control

Before shipping our gear, we conduct rigorous testing to ensure its quality and provide a comprehensive quality report.

1. Dimension Report:A full measurement and record report for 5 pieces product.

2. Material Certificate: Raw material report and the results of spectrochemical analysis

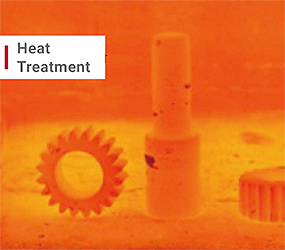

3. Heat Treatment Report: the results of hardness and microstructural testing

4. Accuracy Report: a comprehensive report on K-shape accuracy including profile and lead modifications to reflect your product quality.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

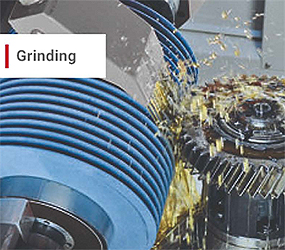

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package