Suppliers miniature steel cylindrical gear spur gear pinion gear for power transmission

Spur Gear Transmission

Spur gear transmission is one of the most fundamental and widely used forms of mechanical power transmission. Spur gears are simple, efficient, and effective for a variety of applications, making them a popular choice in many industries. This article delves into the characteristics, advantages, applications, and considerations involved in spur gear transmission.

Characteristics of Spur Gears

Spur gears are characterized by their straight teeth, which are cut parallel to the gear’s axis. This straightforward design makes them relatively easy to manufacture and maintain. Spur gears transmit motion and power between parallel shafts and are known for their high efficiency, as they experience minimal sliding friction between teeth.

Advantages of Spur Gear Transmission

1. Simplicity: The design of spur gears is straightforward, which makes them easy to manufacture and maintain. This simplicity translates to cost-effectiveness in both production and repair.

2. High Efficiency: Spur gears are highly efficient, with efficiency rates often exceeding 95%. This high efficiency is due to the direct engagement of the teeth, which minimizes frictional losses.

3. Load Distribution: While spur gears primarily distribute load over a single line of contact, they can handle substantial power transmission with proper material selection and design.

4. No Axial Thrust: Unlike helical gears, spur gears do not generate axial thrust, which simplifies the bearing arrangements and reduces the complexity of the overall system.

Applications of Spur Gear Transmission

Spur gears are versatile and find applications in numerous mechanical systems:

● Automobiles: Used in various parts of vehicles, including transmissions and differential systems.

● Industrial Machinery: Common in conveyor systems, lifting equipment, and various types of machinery where reliable power transmission is crucial.

● Consumer Electronics: Found in household appliances, clocks, and other devices that require precise and reliable gear operation.

● Robotics: Essential in the design of robotic arms and other automated systems due to their accuracy and dependability.

Features Of Spur Gears

1. Simple design: Spur gears are simple in design, easy to manufacture and maintain.

2. High efficiency: the parallel teeth of the spur gear make the power transmission efficiency between the shafts high.

3. Low noise: Compared with other types of gears, the noise level of spur gears is relatively low.

4. Wide range of sizes: Spur gears are available in a variety of sizes for a variety of applications.

Quality Control

Before shipping our gear, we conduct rigorous testing to ensure its quality and provide a comprehensive quality report.

1. Dimension Report:A full measurement and record report for 5 pieces product.

2. Material Certificate: Raw material report and the results of spectrochemical analysis

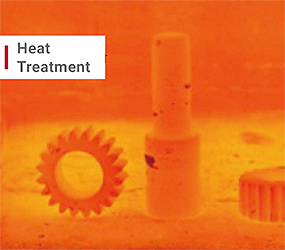

3. Heat Treatment Report: the results of hardness and microstructural testing

4. Accuracy Report: a comprehensive report on K-shape accuracy including profile and lead modifications to reflect your product quality.

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

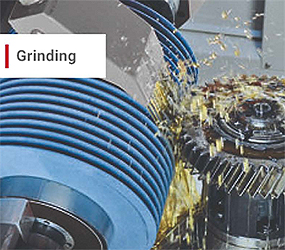

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package