Supplier customized differential spider gear with Rapid Prototype Testing

What Are Spider Gears For?

What are spider gears for?

Spider gears are a crucial component in a vehicle's differential system. They serve several key functions that are vital for the vehicle's performance and handling:

1. Allowing Wheel Speed Differentiation:

Spider gears enable the wheels on the same axle to rotate at different speeds. This is essential when a vehicle turns, as the outer wheels travel a greater distance than the inner wheels. Without this capability, the tires would experience significant scrubbing and wear, and the vehicle would have difficulty maneuvering smoothly.

2. Distributing Torque:

These gears help distribute torque from the driveshaft to the wheels. By allowing for differential wheel speeds, spider gears ensure that torque is applied evenly, which is crucial for maintaining traction and stability, especially on uneven or slippery surfaces.

3. Enhancing Vehicle Handling:

By accommodating the speed differences between the inner and outer wheels during turns, spider gears contribute to better handling and control. This function is vital for safe and predictable vehicle behavior, particularly in high-speed or tight cornering scenarios.

4. Reducing Wear and Tear:

Properly functioning spider gears reduce the strain on other drivetrain components. By allowing the wheels to rotate at their required speeds, these gears prevent excessive wear on tires and other parts of the differential system.

Overall, spider gears are fundamental to the differential system's ability to provide smooth and efficient power distribution to the wheels, enhancing both the performance and longevity of the vehicle.

Manufacturing Plant

Flow of Production

Raw Material

Rough Cutting

Turning

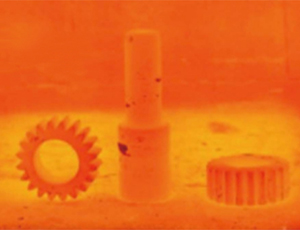

Quenching and Tempering

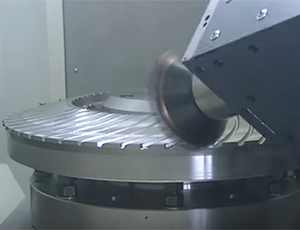

Gear Milling

Heat Treatment

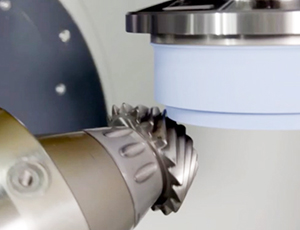

Gear Grinding

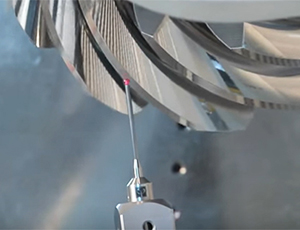

Testing

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

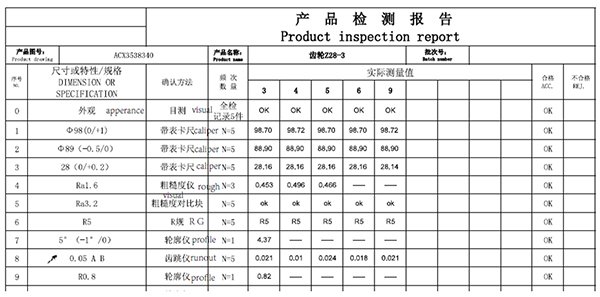

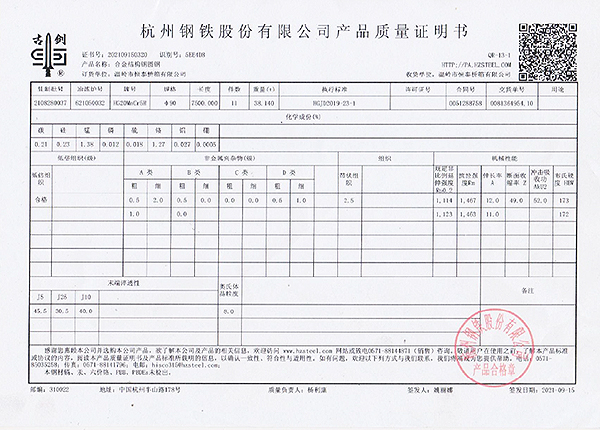

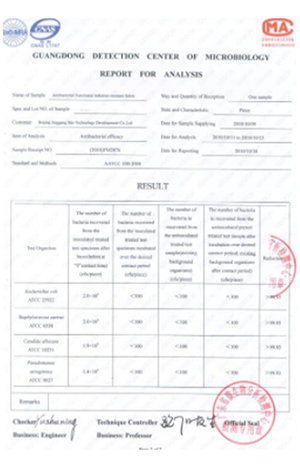

We will provide comprehensive quality documents for your approval before shipping.

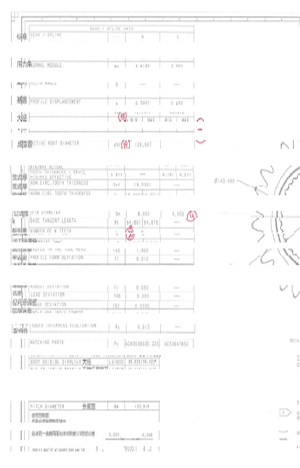

Drawing

Dimension Report

Heat Treatment Report

Accuracy Report

Material Report

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package