At Michigan Gear, quality is our top priority. With our ISO 9001 certification, IATF16949 quality management system and ISO 14001 environmental system certification, We take quality control seriously and follow strict guidelines and standards to ensure that every product/service we provide meets or exceeds our customers' expectations.

We will provide comprehensive support throughout the product design, prototype test, production and after-sales process. Rely on the expertise and experience of our team to provide fast, reliable and first-class service.

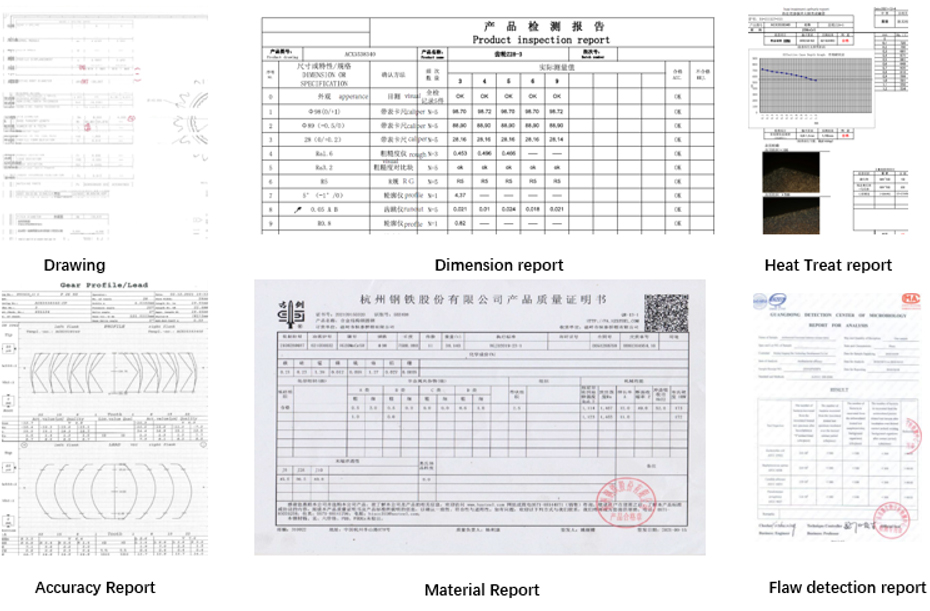

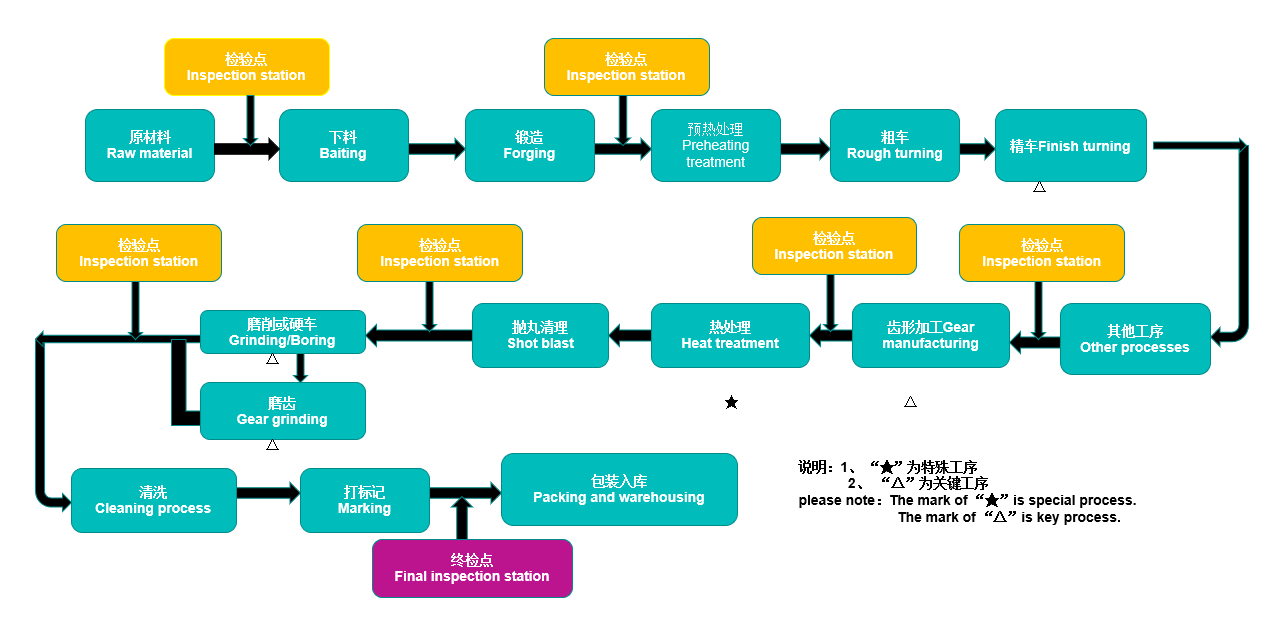

Quality Control Process

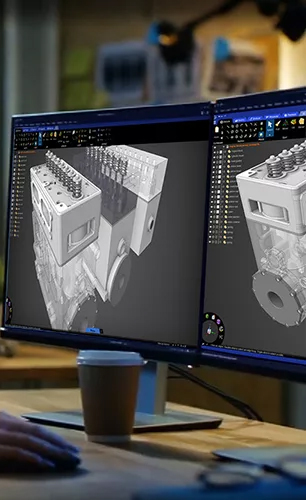

Design Review

This involves inspecting the gear design for accuracy and compliance with engineering standards.

1. CAD software: Computer-aided design (CAD) software such as SolidWorks, AutoCAD, and Inventor can be used to create and analyze 3D models of gears. It allows for accurate design and analysis of gear performance parameters.

2. Gear design software: such as KISSsoft, MDESIGN, and AGMA GearCalc that can be used to analyze gear designs, calculate the required parameters, and validate designs.

3. Finite element analysis (FEA) software: FEA software such as ANSYS, ABAQUS, and Nastran can be used to perform stress and load analysis on gears and their components. This tool helps to ensure that the gear design can withstand the loads and stresses that it will encounter during operation.

4. Prototype testing equipment: Prototype testing machines such as dynamometers and gear test rigs can be used to test the performance of prototype gears and validate their functionality. This equipment helps to ensure that the gears meet the desired performance requirements before full-scale production.

Material Inspection Lab

1. Chemical composition test of raw materials

2. Analysis of mechanical properties of materials

The raw material intended for gear manufacturing is tested to ensure the necessary properties, such as strength, toughness, and wear resistance, meet the required standards.

Testing equipment used may include:

High-precision Metallographic Microscopes produced by Olympus, Micro Hardness Tester, Spectrograph, Analytical Balance, Hardness Testers, Tensile Testing Machines, Impact Testers and End Quenching Tester etc.

Dimensional Inspection

The inspection also includes measuring the surface profile and roughness, back cone distance, tip relief, pitch line runout, and other critical gear parameters.

German Mahr High Precision Roughness Contour Integrated Machine.

Swedish Hexagon Coordinate Measuring Machine.

German Mahr Cylindricity Measuring Instrument.

German ZEISS Coordinate Measuring Machine.

German Klingberg Gear Measuring Instrument(P100/P65).

German Mahr Profile Measuring Instrument etc.

Our Promise

We sincerely hope that our customers will be satisfied with our products. Michigan Gears solemnly promises to provide a one-year warranty on all products if defects do not match the drawings. The customer has the right to request the following options.

1. Returns and Exchanges

2. Repair the product

3. Refund of the original price of the defective product.