Maximize Medical Power Tool Performance with High Torque Planetary Gearboxes

Basic Info

| Model NO | Two Speed-ratiatio Planetary Gearbox |

| Type | Planetary Gear Box |

| High Temperature Stability | 1000℃ |

| Applications | Medical Device, Power Tool |

| Transport Package | Carton |

| Trademark | SMM |

| HS Code | 85011099 |

| Production | Customized |

| Characterisitics | Dual Ratio in One Gearbox |

| Accuracy Degree | ISO 6 |

| Dimension | Customized |

| Specification | RoHS, CE |

| Origin | China |

| Production Capacity | 600, 000PCS/Year |

Basic characteristics of planetary gears in medical power tools

Planetary gears are an important part of the design and functionality of medical power tools. These gears are specifically designed to meet the demanding requirements of medical equipment, ensuring precision, reliability and efficiency. Understanding the basic characteristics of planetary gears used in medical power tools is critical for manufacturers and healthcare professionals.

1. Compact and lightweight design:

Planetary gears are known for their compact, lightweight design, making them ideal for medical power tools where space is often limited. Their ability to provide high transmission ratios in a small package allows the creation of more ergonomic portable medical devices, improving overall usability and operability for healthcare professionals.

2. High torque transmission:

Medical power tools often require high torque transmission to effectively perform a variety of tasks, such as drilling, cutting or precision movements. Planetary gears excel in this regard, providing a high torque-to-size ratio, which is crucial to ensuring the tool can deliver the necessary power without compromising its compact design.

3. Smooth and precise operation:

Precision is critical in medical procedures, and planetary gears are designed to provide smooth, precise operation. This property is crucial for medical power tools used in precision surgeries or complex procedures, where even the slightest deviation can have serious consequences. The inherent stability and low backlash of planetary gears contribute to the overall accuracy and reliability of the tool.

4. Low noise and low vibration:

In medical environments, minimizing noise and vibration is critical to patient comfort and surgical accuracy. The planetary gears are engineered to operate with minimal noise and vibration, ensuring quieter, more stable performance of the power tool. This feature is especially important in the surgical setting, where a calm and controlled environment is critical.

5. Durability and lifespan:

Medical power tools are often subjected to rigorous and demanding use, requiring durable and long-lasting components. Planetary gears are constructed to withstand continuous operation and heavy loads, making them a reliable choice for medical equipment that requires consistent performance over time.

In summary, the characteristics of planetary gears play a vital role in the design and functionality of medical power tools. Its compact design, high torque transmission, precise operation, low noise and vibration, and durability make it an integral component in ensuring the effectiveness and safety of medical devices used in a variety of medical environments. Understanding and utilizing these fundamental characteristics is critical to driving the development of innovative and reliable medical power tools.

Manufacturing Plant

We are proud to offer a state-of-the-art production facility covering an impressive 200,000 square meters. Our factory is equipped with the latest advanced production and inspection equipment to ensure that we can meet the diverse needs of our customers. Our commitment to innovation is reflected in our most recent acquisition - the Gleason FT16000 five-axis machining center.

- Any modules

- Any number of teeth required

- Highest accuracy grade DIN5

- High efficiency, high Precision

We are able to offer unrivaled productivity, flexibility and economy for small batches. Trust us to deliver quality products every time.

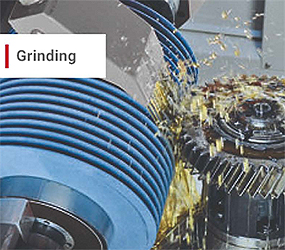

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

1. Bubble drawing

2. Dimension report

3. Material certificate

4. Heat treatment report

5. Accuracy degree report

6. Part pictures, videos

Packages

Inner Package

Inner Package

Carton

Wooden Package