Zerol Bevel Gears for Robotic Systems

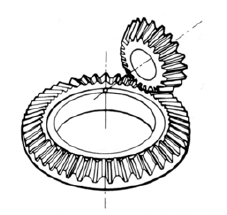

Definition of Zerol Bevel Gears

Zerol bevel gears are a special type of bevel gear with curved teeth and a unique tooth profile that run smoother and quieter than traditional straight cut bevel gears.

Some properties of zerol bevel gears include:

- Quieter operation due to curved teeth

- Higher carrying capacity

- Reduce bounce

- Improve efficiency

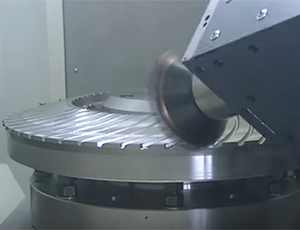

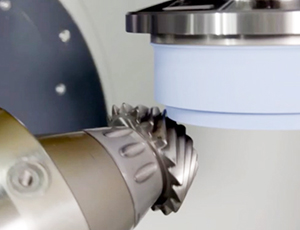

Zerol bevel gears can be manufactured using a variety of processes including CNC machining, hobbing or shaping. The manufacturing process used will depend on factors such as the materials used and the precision required.These types of gears are commonly used in applications such as automotive, aerospace, robotics and industrial machinery where quiet and efficient operation is important.

Manufacturing Plant

Flow of Production

Raw Material

Rough Cutting

Turning

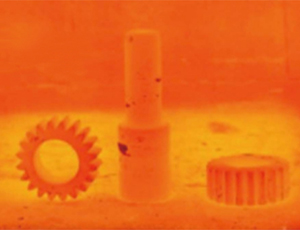

Quenching and Tempering

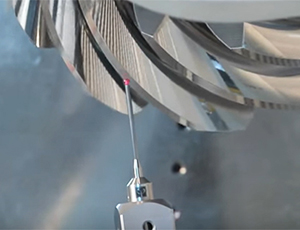

Gear Milling

Heat Treatment

Gear Grinding

Testing

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

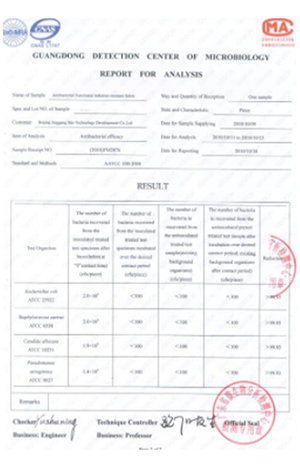

Reports

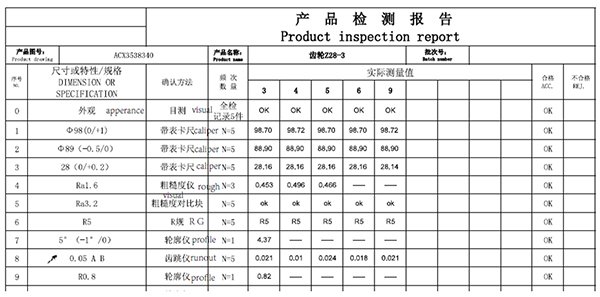

We will provide comprehensive quality documents for your approval before shipping.

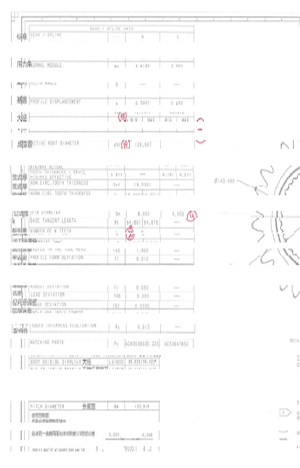

Drawing

Dimension Report

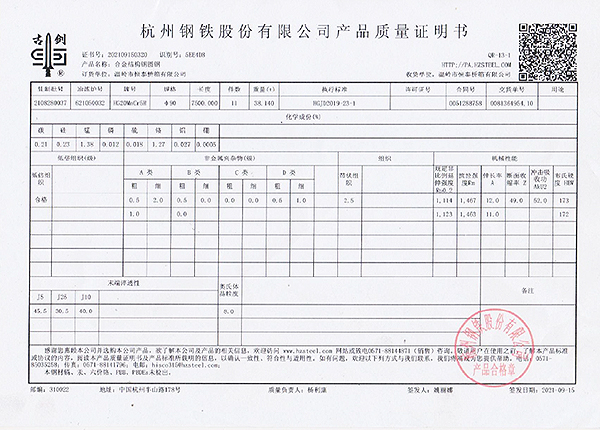

Heat Treatment Report

Accuracy Report

Material Report

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package