Enhancing Efficiency: The Role of Planetary Gears in Home Appliances

Appearance Dimension

Characteristics of planetary gears used in electrical appliances

When it comes to mechanical power transmission, planetary gear systems have proven to be a popular choice for a variety of applications. Its unique design combines efficiency, compactness and noise reduction, making it a versatile solution for every industry.

One of the main advantages of planetary gear systems is their high efficiency. With multiple gear stages working together, these systems enable high levels of power transmission with minimal energy loss. This makes them ideal for applications where maximizing efficiency is critical, such as automotive transmissions, industrial machinery and aerospace systems. By efficiently transferring power from one component to another, planetary gear systems help minimize energy waste and improve overall system performance.

In addition to efficiency, planetary gear systems are also known for their compact design and space-saving advantages. Unlike conventional gear systems that typically require more space to achieve the same gear reduction, planetary gears enable high gear ratios in a smaller footprint. This makes them ideal for space-constrained applications such as robotics, medical equipment and automotive drivetrains. The ability to fit high levels of gear reduction into smaller spaces allows engineers to design more compact, lightweight systems without sacrificing performance.

In addition, noise reduction is another important factor in the design of planetary gear systems. The arrangement of gears in a planetary system allows for smoother, quieter operation compared to other gear types. This is particularly valuable for applications where noise levels need to be minimized, such as consumer electronics, office equipment and precision machinery. By reducing noise, the planetary gear system helps provide a more comfortable and enjoyable user experience while maintaining a high level of performance.

◆ The parameter mentioned is a point of reference, and we are capable of adjusting it to align with your specific needs in a practical application.

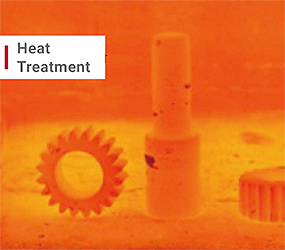

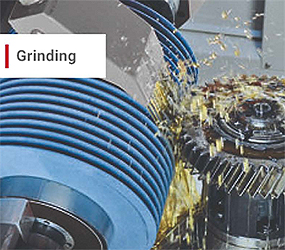

Manufacturing Plant

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package