Enhance Your Vehicle’s Performance with High-Quality Differential Spider Gears

Function and Importance of Differential Spider Gears

Differential spider gears play a crucial role in the mechanics of a vehicle's differential system, enabling smooth and efficient power distribution to the wheels. These gears are essential for allowing wheels to rotate at different speeds, which is particularly important when a vehicle turns. During a turn, the outside wheels travel a greater distance than the inside wheels, necessitating a difference in rotational speed. Spider gears accommodate this disparity, ensuring that each wheel receives the appropriate amount of torque to maintain traction and stability.

The functionality of spider gears directly impacts a vehicle's handling and performance. By facilitating the independent rotation of wheels, these gears prevent tire scrubbing and excessive wear, contributing to smoother and more controlled maneuvering. Additionally, spider gears help distribute power evenly between the wheels, enhancing traction and preventing slippage, which is vital for safe driving in various conditions.

Proper maintenance of spider gears is essential to prevent premature wear and potential failure. Regular lubrication reduces friction and heat, preserving the integrity of the gears and the overall differential system. Neglecting maintenance can lead to significant damage, resulting in costly repairs and compromised vehicle performance.

Overall, the importance of differential spider gears lies in their ability to balance wheel speeds and distribute torque effectively, ensuring optimal vehicle performance, safety, and longevity.

Manufacturing Plant

Flow of Production

Raw Material

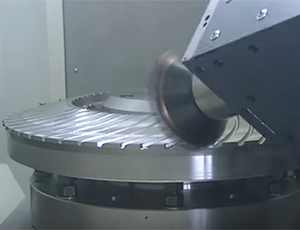

Rough Cutting

Turning

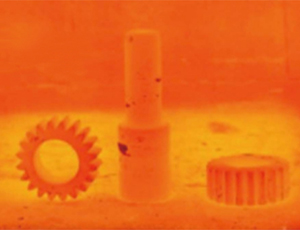

Quenching and Tempering

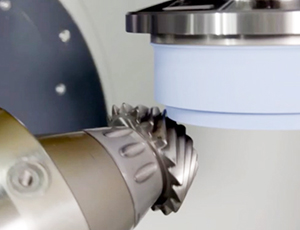

Gear Milling

Heat Treatment

Gear Grinding

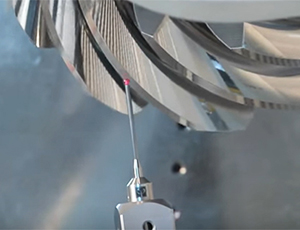

Testing

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Reports

We will provide comprehensive quality documents for your approval before shipping.

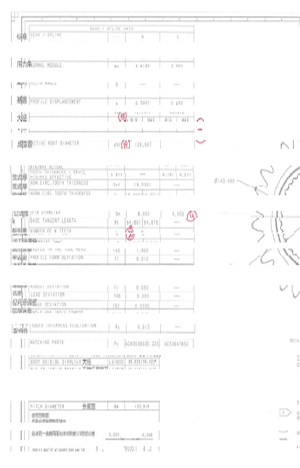

Drawing

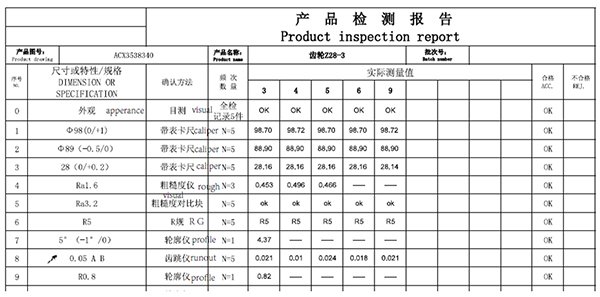

Dimension Report

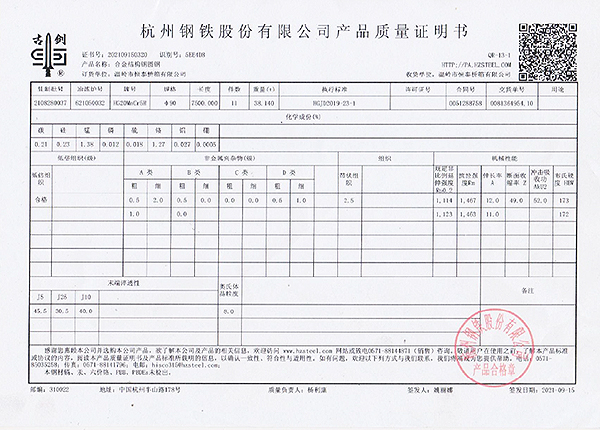

Heat Treatment Report

Accuracy Report

Material Report

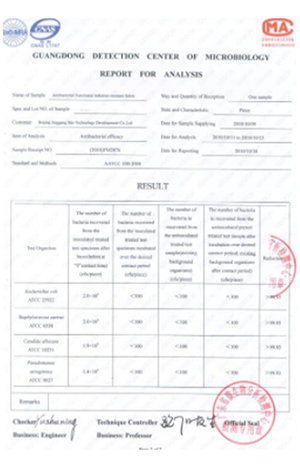

Flaw Detection Report

Packages

Inner Package

Inner Package

Carton

Wooden Package