Enhance Your Kneading Efficiency: The Role of Planetary Gears in Industrial Mixers

The definition of planetary gear

A planetary gear is a type of gear system consisting of three key components:

1. Sun Gear: The central gear around which the other gears rotate.

2. Planet Gears: These gears rotate around the sun gear. Multiple planet gears (usually three or more) are evenly spaced around the sun gear and mesh with it.

3. Ring Gear: An outer gear that encircles the planet gears and meshes with them.

In this arrangement, the planet gears also rotate around their own axes while orbiting the sun gear, hence the name "planetary gear." The entire system can rotate, and the components can be arranged in various ways depending on the application. This design allows for efficient torque transmission, compact size, and the ability to achieve high gear ratios.

Planetary gears are commonly used in applications such as automatic transmissions, industrial machinery, and robotics due to their compactness and ability to handle high loads.

Characteristics of planetary gear

Planetary gears are a type of gear system that features several key characteristics making them highly efficient and versatile for a variety of applications. Here are the primary characteristics of planetary gears:

1. Compact Design:

- Planetary gear systems are compact and can transmit a high amount of torque in a relatively small space. The arrangement of the gears allows for efficient power transmission.

2. High Torque Density:

- These systems are designed to handle a high torque load compared to other gear configurations of similar size, which is why they are often used in heavy-duty applications like industrial machinery and automotive transmissions.

3. Efficient Power Distribution:

- In a planetary gear set, power is distributed among multiple gear meshes, which makes the system highly efficient, with minimal energy loss.

4. Balanced Load Distribution:

- The planetary arrangement allows the load to be distributed among multiple planets, reducing wear on individual gears and increasing the overall lifespan of the system.

5. Multiple Gear Ratios:

- Planetary gear systems can provide various gear ratios in a compact space. This flexibility allows for a wide range of speed and torque outputs, which is essential in applications like gearboxes.

6. Low Noise and Vibration:

- Due to the way the gears mesh and the load distribution across multiple planets, planetary gears tend to operate smoothly and quietly, with reduced vibration.

7. High Efficiency:

- These gear systems typically exhibit high efficiency, often around 95%, due to the multiple gear contacts and optimized power transmission.

8. Durability and Robustness:

- Planetary gear systems are designed to handle heavy loads and high levels of stress, making them durable and suitable for harsh environments and demanding applications.

9. Versatility:

- Planetary gears can be used in various configurations depending on the requirements of the application, such as for speed reduction or increasing torque.

These characteristics make planetary gears ideal for industries such as automotive, aerospace, robotics, and heavy machinery, where precision, durability, and high torque are critical.

Quality Control

Before shipping our gear, we conduct rigorous testing to ensure its quality and provide a comprehensive quality report.

1. Dimension Report:A full measurement and record report for 5 pieces product.

2. Material Certificate: Raw material report and the results of spectrochemical analysis

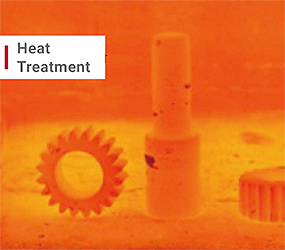

3. Heat Treatment Report: the results of hardness and microstructural testing

4. Accuracy Report: a comprehensive report on K-shape accuracy including profile and lead modifications to reflect your product quality.

Manufacturing Plant

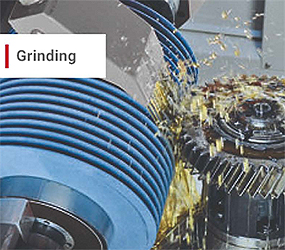

Top ten the first-class enterprises in China are equipped with the most advanced manufacturing, heat treatment and testing equipment, and employ more than 1,200 skilled employees. They have been credited with 31 breakthrough inventions and have been awarded 9 patents, solidifying their position as an industry leader.

Flow of Production

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package