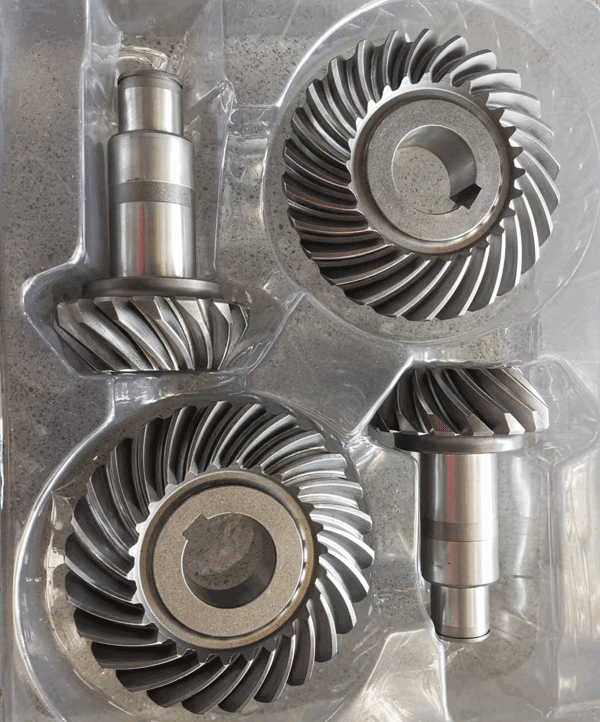

Ground Spiral Bevel Gears for Construction Machinery

Definition of Bevel Gears

A bevel gear is a gear that transmits power between intersecting shafts. They are conical and the teeth cut along the edge of the cone. Bevel gears are commonly used in a range of applications including automotive, aerospace, industrial equipment and more.

Characteristics of bevel gears include their ability to transmit power and torque between intersecting shafts at different angles. These gears provide smooth operation and are designed to handle heavy loads and high speeds. They are also durable and require minimal maintenance.

There are several types of machining methods for making bevel gears, including:

- Hobbing: This method involves using a hobbing machine to cut teeth into a gear blank.

- Milling: Milling machines are used to machine straight teeth on gears.

- Grinding: This method involves shaping and finishing the teeth of the gear using a grinding wheel.

- Grinding: Grinding is a high-precision method that produces exceptionally smooth and precise teeth through the use of grinding tools.

Manufacturing Plant

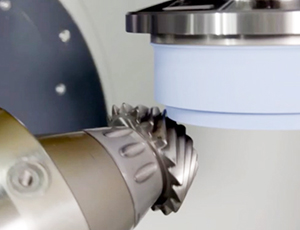

Our company has a production area of 200,000 square meters, equipped with the most advanced production and inspection equipment to meet customers' requirements. In addition, we have recently introduced a Gleason FT16000 five-axis machining center, the largest machine of its kind in China, specially designed for gear manufacturing according to the cooperation between Gleason and Holler.

- Any modules

- Any number of teeth required

- Highest accuracy grade DIN5

- High efficiency, high Precision

We are able to offer unrivaled productivity, flexibility and economy for small batches. Trust us to deliver quality products every time.

Flow of Production

Raw Material

Rough Cutting

Turning

Quenching and Tempering

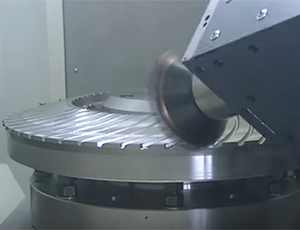

Gear Milling

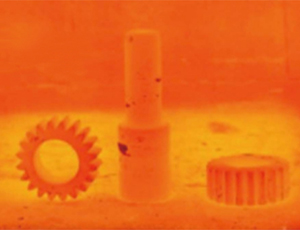

Heat Treatment

Gear Grinding

Testing

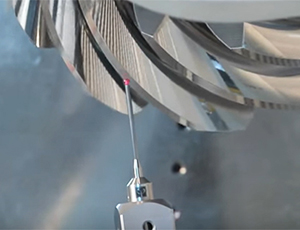

Inspection

We have invested in the latest cutting-edge testing equipment, including Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument and Japanese roughness testers etc. Our skilled technicians use this technology to perform accurate inspections and guarantee that every product that leaves our factory meets the highest standards of quality and precision. We are committed to exceeding your expectations every time.

Packages

Inner Package

Inner Package

Carton

Wooden Package