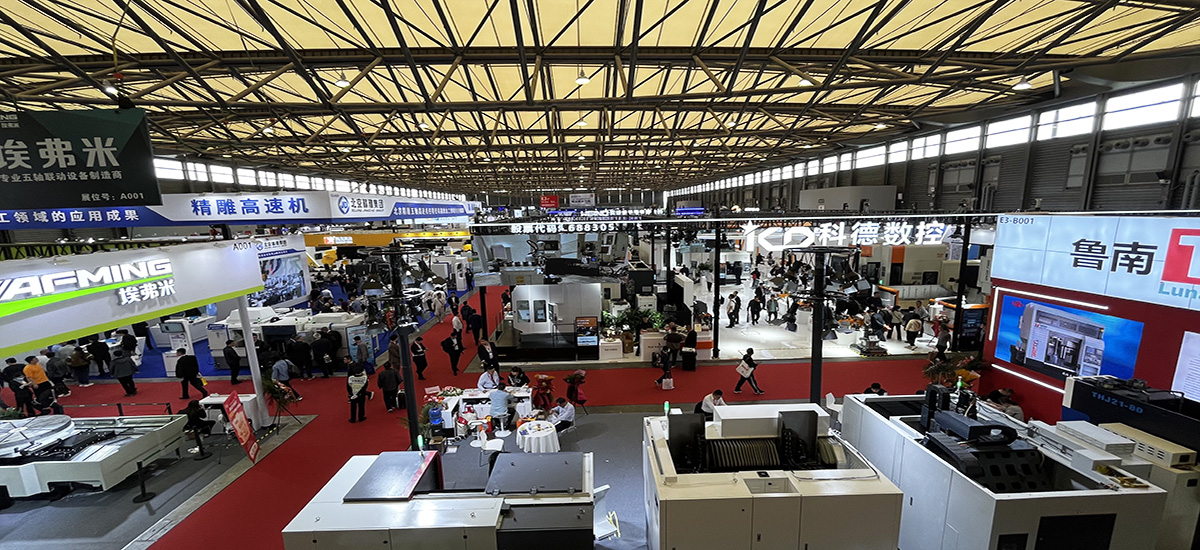

On the morning of April 8, 2024, the 13th China CNC Machine Tool Expo (CCMT2024) opened at the Shanghai New International Expo Center. This event, hosted by the China Machine Tool Industry Association, has garnered significant attention as the largest machine tool exhibition in China. CCMT2024 boasts the participation of nearly 2,000 machine tool companies from 28 countries and regions, establishing itself as a platform to showcase the most cutting-edge products and technologies in the global machine tool industry.The expo aims to emphasize technological advancements, new processes, and the latest achievements in digital intelligence integration within the industry.

One of the well-known exhibitors of CCMT2024 is Shanghai Michigan, a professional gear manufacturing company that has been providing customers with customized services for various gears. We focus on precision and quality, and our products include steel spur gears, steel helical gears, spiral bevel gears, and hypoid gears. The company’s participation in the show demonstrates its commitment to showcasing its expertise and capabilities in gear manufacturing. Visitors can gain an in-depth understanding of the latest developments and solutions provided by Shanghai Michigan and contribute to the overall vitality of the exhibition.

"Three Highlights" Interpret the New Path of Industry Development

1. High Speed and Efficiency

The GENERTEC HMU160 horizontal five-axis machining center is a flagship product for industries, particularly in the realm of new energy vehicles. Notably, its linear axis boasts a rapid moving speed of 100m/min and an acceleration of 1g. Additionally, the rotating axis is directly driven by a torque motor, achieving speeds exceeding 40r/min. These features enable the machine to operate at high speeds, significantly reducing processing assistance time.

2. Composite Integration

The GENERTEC HTM80150 horizontal turning and milling composite machining center, CXH5225x20/16 double column vertical turning and milling machining center, and other machines possess the characteristics of integrating multiple functions into a single machine and enabling composite processing of multiple processes. These machines can accomplish comprehensive processing from rough to finished products, leading to significant enhancements in machining accuracy and production efficiency.

3. Intelligent Machine Tools

The VMU63P five-axis vertical machining center is equipped with intelligent functions such as environmental thermal adaptation and autonomous safety protection, which serve to enhance product stability. The GMC125u/t five-coordinate machining center is equipped with a comprehensive machine thermal control system and a measurement feedback system, resulting in improved accuracy and stability. Additionally, the MGK7450 × 2H CNC high-precision vertical grinder is equipped with internal feedback oil film self-balancing technology, which complements and reinforces functions such as online measurement and grinding vibration detection.

Post time: Apr-12-2024