Differential gears have long been a crucial component in automotive engineering, enabling the smooth and efficient transfer of power from the engine to the wheels. Over the years, significant advancements have been made in differential technology, enhancing performance, durability, and efficiency. In this blog, we will explore some of the latest innovations in differential gears and their applications, highlighting how companies like Subaru and Shanghai Michigan Mechanical Manufacture are pushing the boundaries of this essential technology.

Innovations in Differential Technology

Advanced Materials

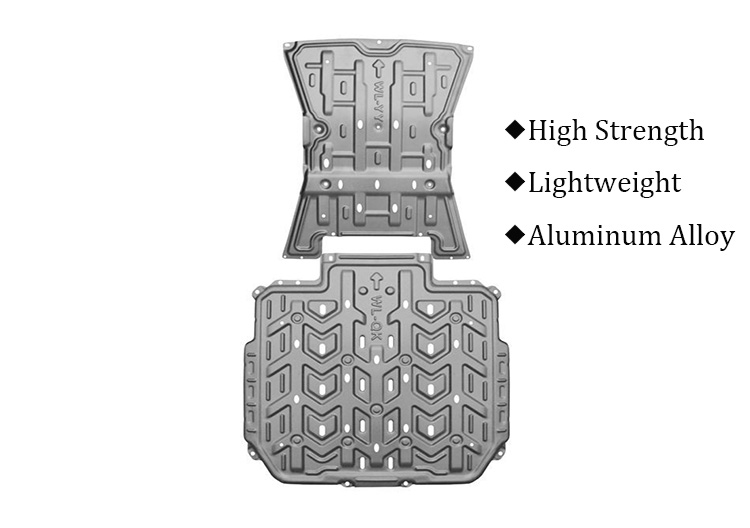

One of the key areas of innovation in differential gears is the use of advanced materials. Traditional differentials were typically made from steel or cast iron, which, while durable, are relatively heavy and can contribute to increased fuel consumption. Modern differentials are now often constructed from high-strength, lightweight materials such as aluminum alloys and advanced composites. These materials not only reduce the overall weight of the vehicle, enhancing fuel efficiency, but also improve the durability and longevity of the differential gears.

Design Improvements

Design improvements have also played a significant role in advancing differential technology. Engineers are continually refining the geometry of gear teeth, the housing design, and lubrication systems to reduce friction and wear. These improvements result in smoother operation, reduced noise, and longer service intervals. Additionally, innovations such as limited-slip differentials and electronically controlled differentials provide better traction and stability, especially in challenging driving conditions.

Case Study: Subaru Crosstrek Wilderness 2024

Subaru's 2024 Crosstrek Wilderness serves as an excellent example of how modern differential innovations are being applied in real-world scenarios. This vehicle is equipped with upgraded differentials designed specifically for enhanced off-road capabilities and improved towing capacity. The differentials in the Crosstrek Wilderness feature advanced materials and a robust design that can withstand the rigors of off-road driving while providing superior traction and control. This allows drivers to tackle rough terrains with confidence, knowing that their vehicle's differential gears can handle the demands of such environments.

Shanghai Michigan Mechanical Manufacture's Contribution

Shanghai Michigan Mechanical Manufacture (SMM) is at the forefront of differential gear technology, leveraging cutting-edge materials and design techniques to produce high-performance differentials for various automotive applications. SMM's differentials are known for their exceptional durability and efficiency, making them a preferred choice for automotive manufacturers around the world. By incorporating the latest advancements in materials science and engineering, SMMM ensures that their differential gears deliver optimal performance and reliability, even under the most demanding conditions.

Applications Beyond Automotive

While differential gears are most commonly associated with automotive applications, their use extends to other industries as well. Heavy machinery, aerospace, and robotics are just a few examples where differential technology plays a crucial role. In these applications, the ability to efficiently distribute power and provide precise control is essential for operational success.

Conclusion

The ongoing advancements in differential gear technology, from the use of advanced materials to innovative design improvements, are revolutionizing the automotive industry and beyond. Companies like Subaru and Shanghai Michigan Mechanical Manufacture are leading the charge, demonstrating how these innovations can enhance performance, durability, and efficiency. As we look to the future, it is clear that differential gears will continue to be a critical component in the development of high-performance, reliable machinery across various sectors.

Post time: Jul-19-2024