Blog

-

Understanding Cycloidal Gearboxes | Single-stage vs Multi-stage

It's no secret that cycloidal gearboxes are important in mechanical engineering, especially when it comes to precision motion control and efficient power transmission. The gear systems differ from harmonic wave/strain wave gearboxes by using a cycloidal disk and needle b...Read more -

In-depth analysis of the use and reduction ratio of cycloid pinwheel reducers

Uses of Cycloidal Pinwheel Reducers 1. Industrial Manufacturing Cycloidal pinwheel reducers play an indispensable role in all aspects of industrial manufacturing. On automated production lines, they precisely control the speed and torque of robotic arms, ensuring the acc...Read more -

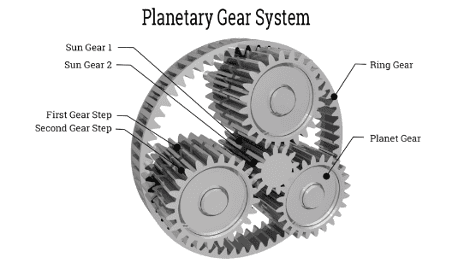

Planetary Gearbox: How It Works, Types, and Advantages?

A planetary gearbox is a compact and efficient gear system used in various industrial applications. Known for its high torque transmission and space-saving design, it consists of a central sun gear, planetary gears, a ring gear, and a carrier. Planetary gearboxes are wid...Read more -

How to Choose the Right Planetary Gearbox for Your Application?

Selecting a Planetary Gearbox requires you to consider factors that impact performance and reliability. Review the table below for common operational requirements in manufacturing: Requirement Description Service Factor Handles overloads and affects longevity. Gea...Read more -

How to Choose the Right Planetary Gearbox for Robotic Arms

Selecting the appropriate planetary gearbox is crucial for optimizing the performance, efficiency, and reliability of robotic arms. Whether you're involved in industrial manufacturing, medical robotics, or research and development, the following key factors will guide yo...Read more -

Gleason and Klingenberg bevel gear

Gleason and Klingenberg are two prominent names in the field of bevel gear manufacturing and design. Both companies have developed specialized methods and machinery for producing high-precision bevel and hypoid gears, which are widely used in automotive, aerospace, and i...Read more -

worm and worm gear

A worm and worm gear is a type of gear system that consists of two main components: 1.Worm – A threaded shaft resembling a screw. 2.Worm Gear – A toothed wheel that meshes with the worm. Key Characteristics High Reduction Ratio: Provides significant speed reduction in a compact space (e.g., 20:...Read more -

planetary gear

A planetary gear (also known as an epicyclic gear) is a gear system consisting of one or more outer gears (planet gears) revolving around a central (sun) gear, all held within a ring gear (annulus). This compact and efficient design is widely used in automotive transmissions, industrial machinery...Read more -

gear lifetime

The lifetime of a gear depends on several factors, including material quality, operating conditions, maintenance, and load capacity. Here’s a breakdown of key factors affecting gear lifespan: 1. Material & Man...Read more -

Gear Noise

Gear noise is a common issue in mechanical systems and can arise from various factors, including design, manufacturing, installation, or operational conditions. Here are the primary causes and potential solutions: Common Causes of Gear Noise: 1.Incorrect Gear Meshing Mis...Read more -

Gear Hobbing Cutter: Overview, Types, and Applications

A gear hobbing cutter is a specialized cutting tool used in gear hobbing—a machining process that produces spur, helical, and worm gears. The cutter (or "hob") has helical cutting teeth that progressively generate the gear profile through a synchronized rotary motion wit...Read more -

Pinion and Gear: Definition, Differences, and Applications

1. Definitions Pinion: The smaller gear in a meshing pair, often the driving gear. Gear: The larger gear in the pair, usually the driven component. 2. Key Differences Parameter Pinion Gear Size Smaller (fewer teeth) Larger (more teeth) Role Typically the driver (input) Typically the driven...Read more